Introduction to ASTM F2052 Standard: Measurement of Magnetically Induced Displacement Force on Medical Devices in a Magnetic Resonance Imaging (MRI) Environment.

When approaching the MRI system, any device containing ferromagnetic materials will be subjected to a displacement force induced by the static magnetic field of the MRI. This field remains active even when no scan is in progress. The risk therefore applies to all objects that might be brought near the machine: instruments, tools, implants, jewelry, keys, handcuffs, cleaning equipment, etc.

The displacement force depends on the spatial variation of the magnetic field. It is sometimes more pronounced on 1.5T MRI systems than on 3 or 7 Tesla units, depending on the distribution of the magnetic field gradient.

Focus on the spatial gradient of the magnetic field

The spatial gradient of the magnetic field, or Spatial Field Gradient (SFG), refers to the spatial variation of the magnetic field. In other words, the ‘slope’ of the magnetic field around the MRI system. Expressed in Teslas per meter (T/m), the maximum SFG value is on the order of 20 T/m in current MRI scanners.

Objective of the ASTM F2052 Standard

The ASTM F2052 standard defines a standardized test method for measuring the displacement force induced by the MRI magnetic field on medical devices.

Principle of the ASTM F2052 Method

The test consists of suspending the medical device from a string and then bringing it close to the MRI system until it reaches an area where the Spatial Field Gradient is near its maximum.

Once the device is in position, the deviation angle of the string relative to the vertical (0°) is recorded. This angle is then used to calculate the magnetic displacement force exerted on the device.

This test requires a stable, non-magnetic measurement stand that is heavy enough to withstand the generated forces and equipped with instruments capable of accurately measuring variations in the magnetic field and the deviation angle of the string.

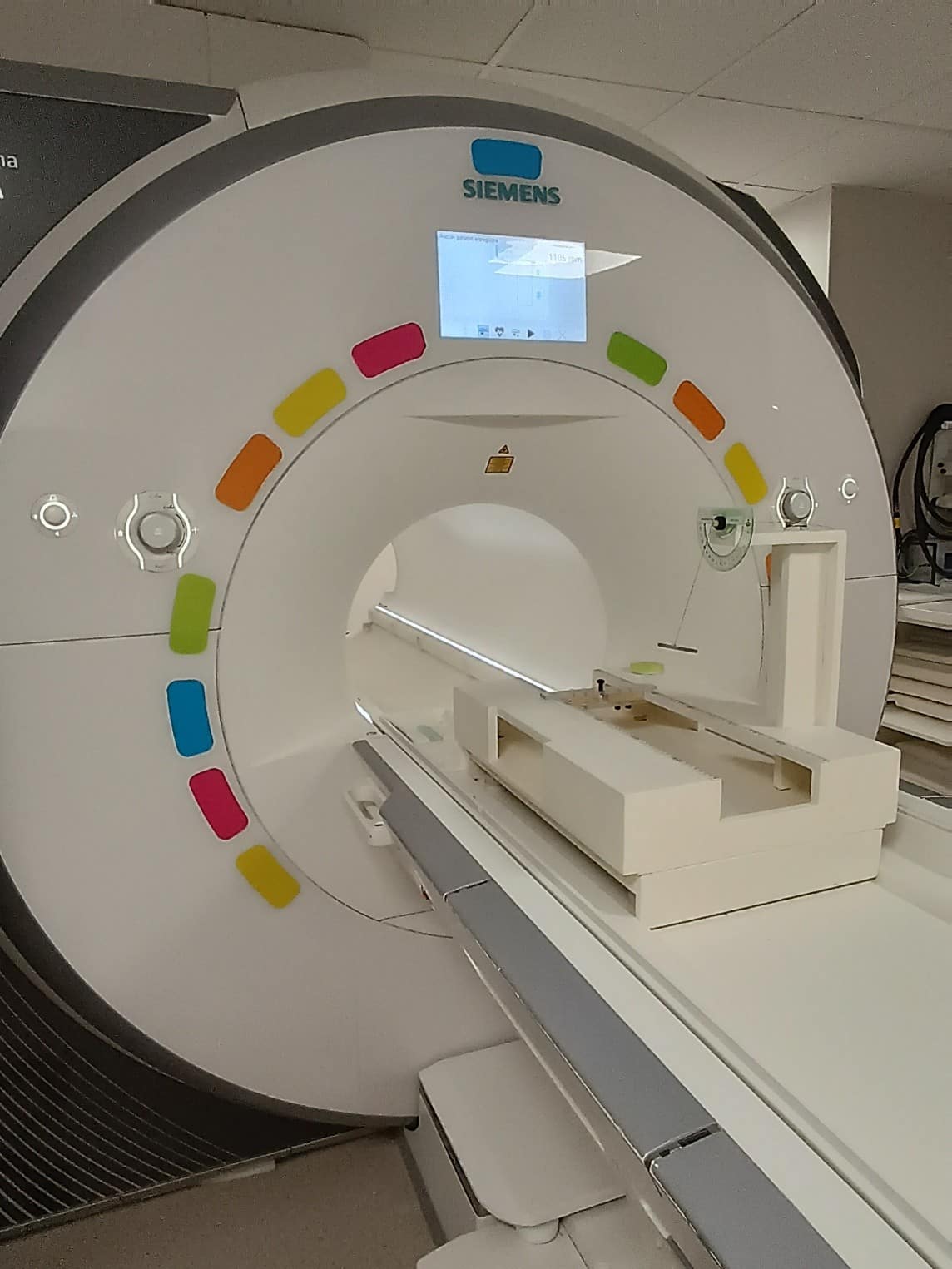

Implementation in our testing laboratory

At Healtis, the measurement of displacement force according to ASTM F2052 is performed under ISO 17025 accreditation, using a test bench specifically designed and qualified for this purpose.

The tests are carried out by authorized and trained personnel, using calibrated instruments that are regularly verified.

Healtis is ISO 17025 accredited (Cofrac Testing Accreditation, No. 1-6320, scope available at www.cofrac.fr).

How are the results of ASTM F2052 tests interpreted?

The ASTM F2052 test makes it possible to quantify the displacement force for exposure to a given magnetic field.

The interpretation of the results aims to determine the maximum Spatial Field Gradient value for which the displacement force will not cause movement, within its intended context. This assumes that the manufacturer defines an acceptance criterion: the minimum force required to cause movement of the device under clinical conditions.

The ASTM F2052 standard suggests using the weight of the device as the acceptance criterion—a generally conservative approach for implants, but sometimes too restrictive, allowing only a low Spatial Field Gradient.

For some loosely secured devices, this criterion may also be insufficient to guarantee the absence of movement.

It is therefore essential to conduct a specific analysis of the clinical context, taking into account the device’s fixation method, in order to define an appropriate acceptance criterion.

To conclude

The ASTM F2052 standard is essential for any manufacturer of metallic or magnetic medical devices wishing to evaluate the behavior of their product in an MRI environment. It provides a standardized method for quantifying the risk of device displacement induced by the magnetic field.

A revision of the ASTM F2052 standard is currently underway as part of ASTM Work Item WK88170. Experts, including some Healtis collaborators, are contributing to the introduction of an additional method based on direct measurement using a dynamometer.

To stay informed about the publication of this new version and all regulatory updates related to MRI safety for medical devices, follow us on LinkedIn!